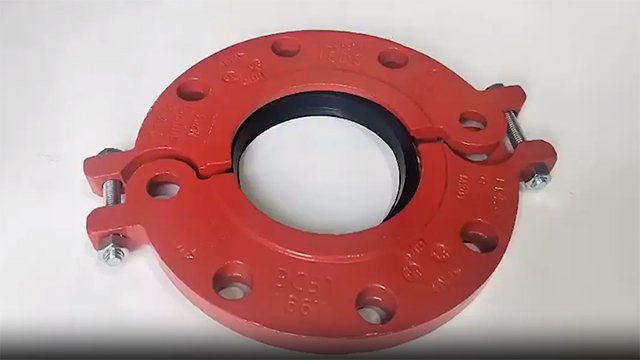

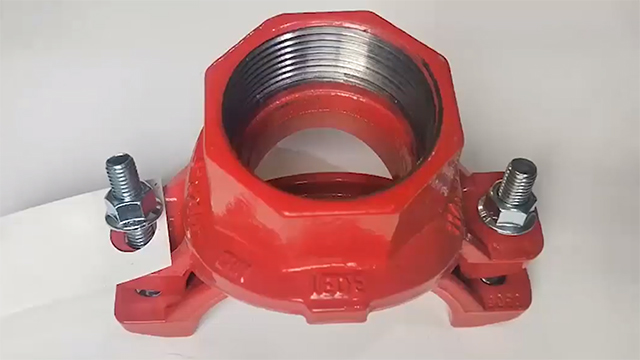

Rigid Grooved Piping System Pipe Coupling

Rigid couplings for grooved piping systems are manufactured to provide rigidity at the assembled joint- similar to the pipe joint being welded or flanged. The ANSI B31.1 Power Piping Code requires a minimum hanger spacing for piping with rigid connections, as does the ANSI B31.9 Building Service Code and NFPA 13 Fire Protection Systems. Underwriters Laboratory defines a rigid pipe connection as one that does not deflect from a center line by more than one (1) degree. After the pipe ends are grooved, a rubber gasket that is suitable for the piping system is stretched over the pipe ends. Coupling segments are then placed over the gasket, and nuts and bolts are fastened, resulting in a secure and leak free joint. Rigid couplings are most often used to assemble horizontal piping that holds the weight and provides a platform for plumbing and accommodates the weight of fluid, fittings, valves and other devices. Grooved pipe couplings are often used in fire protection services, water supply systems, and other process systems that require a higher working pressure.